What are you looking for?

Search

About us

Welcome to Jingdezhen Ceramic Boutique, we were founded in 2018. We aim to promote Jingdezhen's high-quality ceramic products to all parts of the world, so that ceramic lovers around the world can enjoy high-end exquisite porcelain made of high-quality porcelain clay.

We are based in Jingdezhen, China, relying on the high-quality resources of Jingdezhen Ceramics University. We have independent design and research and development capabilities, and have several art masters as the main studio. We can accurately grasp the global trend and integrate it with Chinese porcelain culture.

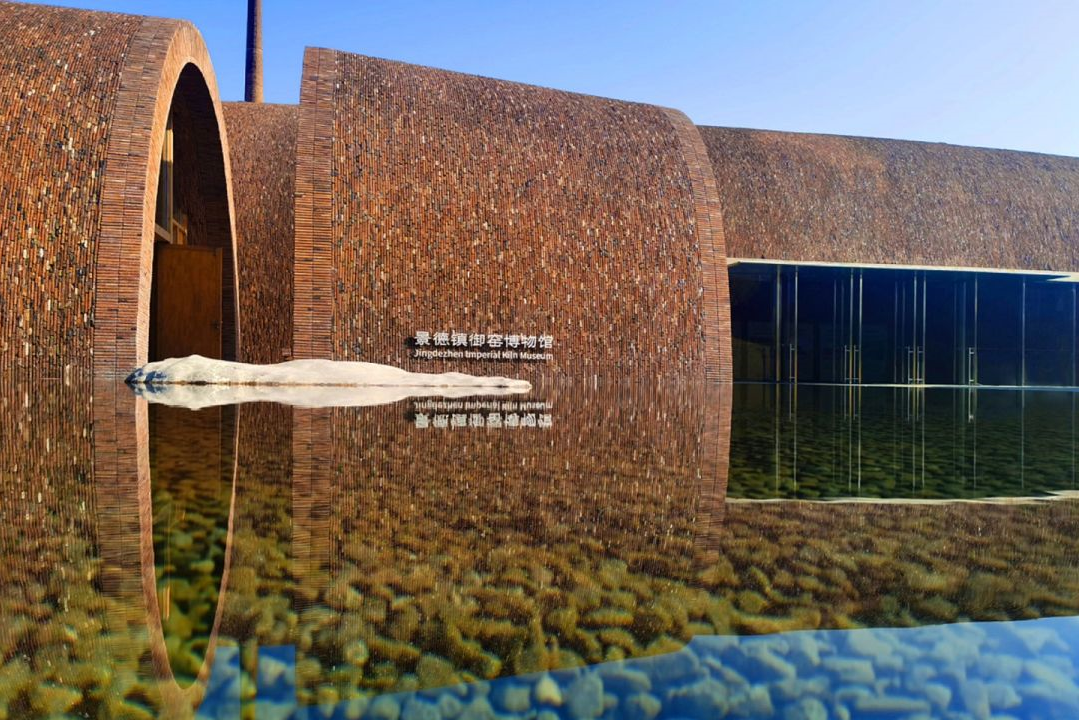

Jingdezhen: A glimpse into a millennium of ceramics

What is Jingdezhen Ceramics?

Jingdezhen porcelain is Chinese porcelain produced in or near Jingdezhen in Jiangxi province in southern China. Jingdezhen may have produced pottery as early as the sixth century CE, though it is named after the reign name of Emperor Zhenzong, in whose reign it became a major kiln site, around 1004. By the 14th century it had become the largest centre of production of Chinese porcelain, which it has remained, increasing its dominance in subsequent centuries. From the Ming period onwards, official kilns in Jingdezhen were controlled by the emperor, making imperial porcelain in large quantity for the court and the emperor to give as gifts.

From the mid-14th century, Jingdezhen began to mass-produce underglaze blue porcelain, whose development it pioneered, making it "one of the world's earliest industrial towns".Much of this was for export, and other styles were produced for the Chinese market.

How to Choose Authentic Jingdezhen Ceramics?

Before you can distinguish the real from the not-so-real, you first need a basic overview of how Jingdezhen ceramics are made.

The traditional way of making Jingdezhen porcelain is a lengthy process that begins with the mining of kaolin and white stone, which is then pulverized and purified with water into a homogenous, muddy texture. Care is given to remove foreign particles or loose paste as these would cause flaws in the porcelain. The prepared paste is then press-molded on a potter’s wheel, where it changes shape in the artisan’s hands, lengthening or shortening, contracting or widening, in a variety of shapes.

Patterns are carved on the body of the porcelain using bamboo, bone or knives. After glazing, the porcelain is sent to the kiln for firing. The last step involves painting on the porcelain – a further low-firing process enhances the colors of the paint. If the colors of the porcelain are as bright as a mirror, you’re on the right path to finding authentic ceramics.

Another tip for choosing high-quality pieces is the sound they make when you clang them together. True porcelain will sound like a crisp bell when you tap two pieces against each other.